Theme: Meeting standards of drug regulations & achieving GxP compliance

GMP and Pharma Audit 2018

February 13, 2018

Dear Friends,

As Mayor of Philadelphia, I am pleased to welcome you to our city for the 8th International Conference and Exhibition on Pharma Audit, GMP, GCP & Quality Control (GMP and Pharma Audit 2018)

GMP-Pharma Audit 2018 will provide a platform for industry leaders around the world to review current pharmaceutical standards and regulations. Discussing auditing practices and GMP compliance standards will ensure the reliable production of medications worldwide.

I would like to commend each participant for their tireless commitment to this important work. Again please accept my best wishes for a successful conference. During your stay, I hope you will take the opportunity to enjoy the historical and cultural attractions that make Philadelphia such a desirable place to visit.

On behalf of the City of Philadelphia, we look forward to hosting you.

Sincerely,

GMP and Pharma Audit 2018 is the learning of ensuring that products are consistently produced and controlled according to quality standards. It is designed to minimize the risks involved in any pharmaceutical production that cannot be eliminated through testing the final product.

GMP covers all aspects of production; from the starting materials, premises and equipment to the training and personal hygiene of staff. Advanced studies are being made to improvise quality of products, reduce safety risk and cost, and enhance international credibility and public image and many more.

The goal of an audit is to express an opinion on the person, organization, system etc. Auditing is a critical function within a pharmaceutical company, under evaluation based on work done on a test basis. Audits are performed to ascertain the validity and reliability of information, also to provide an assessment of a system's internal control. A company that makes medications today must be able to prove that it does so with absolute reliability, under optimal secure conditions, and with extreme uniformity to allow for exact reproduction. Pharmaceutical auditing expertise includes writing and review of validation policies, guidelines and SOP from design qualification to performance qualification steps.

The Auditors responsibility is to express an opinion on these standalone financial statements based on the audit, taken into account the provisions of the Act, the accounting and auditing standards and matters which are required to be included in the audit report under the provisions of the Act and the Rules made there under. An audit involves performing procedures to obtain audit evidence about the amounts and the disclosures in the financial statements. The procedures selected depend on the auditor's judgment, including the assessment of the risks of material misstatement of the financial statements, whether due to fraud or error. In making those risk assessments, the auditor considers internal financial control relevant to the Company's preparation of the financial statements that give a true and fair view in order to design audit procedures that are appropriate in the circumstances, but not for the purpose of expressing an opinion on whether the Company has in place an adequate internal financial controls system over financial reporting and the operating effectiveness of such controls.

Why to attend

To understand the challenges that submitters encounter during the preparation, filing, and management of regulatory submissions

- Explore the latest developments in ISO IDMP standards

- Impact for the future of Product Quality Review?

- Measuring and Monitoring of Quality Assurance: Regulatory Expectations

- To obtain current information about FDA activities

- Benchmark your regulatory strategies with the other leaders

Good Reasons Not to Miss GMP and Pharma Audit 2018

- You can listen to Industry manufacturing experts

- The program focuses both on scientific value and impact on the industrial world

- You can meet companies and stakeholders in the pharmaceutical product development field

Who should attend and Who You’ll Meet?

Directors, Senior Directors, Executive Directors and Vice Presidents, Senior Vice Presidents, patents, attorney, Executive Vice Presidents and Heads, Leaders, Partners of

- Clinical Research Sites

- Pharma, Biotech, Biosimilars, Medical Devices manufacturing departments

- Hospitals, Associations

- Pharmacoepidemology

- Quality Analysts, Consultants

- Documentation Analysts

- Manufacturing Professionals

Clinical research associates, Quality control analysts, Medical Directors, Principal Investigators, Methodologists, and other Regulatory professionals along with Academicians: University Faculties like Directors, Senior Professors, Assistant Professors, Associate Professor, Research Scholars, scientists who are related to clinical and medical research.

Industry professionals with responsibilities in:

- Current Good Manufacturing Practices

- Manufacturing

- Quality Assurance

- Clinical Trial Management/Clinical Trial Supplies

- GxP's

- Clinical Research & Development

- Pharmacovigilance

|

Production |

Quality assurance |

|

Quality control |

Regulatory affairs |

|

Auditing in the pharmaceutical |

Biopharmaceutical industry |

|

Supervisory personnel |

Managers |

|

Quality and regulatory personnel |

Health Care Professionals |

|

R&D Professionals |

Research Scholars |

|

Methodologists |

Regulatory professionals |

|

Clinical Researchers |

Medical Directors |

|

Principal Investigators |

Senior Professors |

|

Assistant Professors |

Scientists |

Track-1: Good Manufacturing Practices: The Gap Within

Good Manufacturing Practice is the part of quality management which ensures that products are consistently produced and controlled according to the quality standards appropriate to their intended use and as required by the marketing authorization, clinical trial authorization or product specification. Good Manufacturing practices conference aims at both production and Quality Control. Current Good Manufacturing Practices (cGMP) is aimed primarily at managing and minimizing the risks inherent in pharmaceutical manufacture to ensure the quality, safety and efficacy of products. FDA regulates the quality of pharmaceuticals very carefully. Current Trends in the FDA is the main regulatory standard for ensuring pharmaceutical quality.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-2: Current Regulations and Quality Standards

Roles of pharmaceutical inspection convention and co-operation scheme (PIC/S) are to improve co-operation in the field of Good Manufacturing Practices between regulatory authorities and the pharmaceutical industry. The FDA regulations and CFR are responsible for protecting and promoting public health through the regulation and supervision of all the products available in the market to ensure patient compliance. EU-GMP guidelines are needed to maintain the products quality which is stricter when compared to WHO-GMP guidelines.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-3: Current GMP Guidelines (cGMP) & GxP in Pharmaceuticals

CGMP refers to the Current Good Manufacturing Practice regulations enforced by the US FDA. CGMPs provide for systems that assure proper design, monitoring, and control of manufacturing processes and facilities. Adherence to the cGMP regulations assures the identity, strength, quality, and purity of drug products by requiring that manufacturers of medications adequately control manufacturing operations. This includes establishing strong quality management systems, obtaining appropriate quality raw materials, establishing robust operating procedures, detecting and investigating product quality deviations, and maintaining reliable testing laboratories.

The purpose of the GxP quality guidelines is to ensure a product is safe and meets its intended use. GxP guides quality manufacture in regulated industries including food, drugs, medical devices and cosmetics.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-4: The Role of 'c' in cGMP

The CGMP requirements were established to be flexible in order to allow each manufacturer to decide individually how to best implement the necessary controls by using scientifically design, processing methods, and testing procedures. The flexibility in these regulations allows companies to use modern technologies and innovative approaches to achieve higher quality through continual improvement. Accordingly, the "C" in CGMP stands for "current," requiring companies to use technologies and systems that are up-to-date in order to comply with the regulations. Systems and equipment that may have been "top-of-the-line" to prevent contamination, mix-ups, and errors 10 or 20 years ago may be less than adequate by today's quality standards.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-5: Good Clinical Practices and Good Laboratory Practices

The role of ICH in designing GCP principles is to provide an ethical treatment to the subjects who are involved in the clinical trials. Conference on Good Clinical Practices is important because it is an international ethical and scientific quality standard for designing, conducting, recording and reporting trials that involve the participation of human subjects. The GLP Principles describe requirements for and provide general guidance on the conduct of all nonclinical health and environmental safety studies, including invitro studies. Pre-clinical trials assess the toxicity of a drug and examine its potential effects on the human body. These trials are conducted in-vitro which is required to proceed with clinical trials. Good laboratory practices should be followed for these pre-clinical trials.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-6: Quality Control

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria that meets the requirements of the client or customer. A major aspect of quality control is the establishment of well-defined controls. These controls help standardize both production and reactions to quality issues. The role of Quality Impact Assessment & effectiveness checks is an essential operation of the pharmaceutical industry. To Perform Quality Control process of Project Management several quality control tools and software’s are required. Quality control also plays a major role in analytical method development so it would be great to attend the quality control summit.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-7: Quality Assurance

Quality assurance is defined as a procedure or set of procedures intended to ensure that a product or service under development meets specified requirements. A quality assurance system is said to increase customer confidence and a company's credibility, to improve work processes and efficiency, and to enable a company to better compete with others. Quality assurance conferences aims at the need for Effective Internal and External Quality Assurance Auditing and it is required, by all active pharmaceutical ingredient (API)/bulk pharmaceutical chemical, medical device and finished pharmaceutical cGMP regulations published worldwide. Quality assurance testing is done by using software called Quality Metrics.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-8: Validation

Validation means establishing documented evidence that provides a high degree of assurance that a specific process will consistently produce a product meeting its predetermined specifications and quality attributes. Validation is an integral part of quality assurance; it involves the systematic study of systems, facilities and processes aimed at determining whether they perform their intended functions adequately and consistently as specified. The Major Phases of validation include Pre validation, Process Validation and Validation maintenance Phase.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-9: Contract and Sterile/Aseptic Manufacturing

Traditional role of Contract manufacturing, also known as outsource manufacturing, is to produce one or more components of a final product in which a company relies on the skills of specialist manufacturers. Six sigma is a long-term, forward-thinking initiative designed to fundamentally change the way corporations do business. It is first and foremost "a business process that enables companies to increase profits dramatically by streamlining operations, improving quality, and eliminating defects or mistakes in everything a company does. Aseptic/sterile production and injectable manufacturing processes require a significant investment in terms of expertise, equipment, process, technology and quality control.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-10: Storage, Distribution, Transportation

Cold chain storage is a temperature-controlled supply chain. An unbroken cold chain is an uninterrupted series of storage and distribution activities which maintain a given temperature range. It is used to help extend and ensure the shelf life of pharmaceutical drugs. Good distribution practice (GDP) deals with the guidelines for the proper distribution of medicinal products for human use. GDP is a quality warranty system, which includes requirements for purchase, receiving, storage and export of drugs intended for human consumption. Supply Chain integrity, enable qualified firms to expedite the importation of active pharmaceutical ingredients and finished drug products.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-11: Formulation Development

Formulation development is to be done only after successful completion of pre-formulation studies. Optimization of existing formulations is required to create new products, Reduce costs, to capitalize on trends with greater profitability, novel formulations for improved delivery of existing dosage forms, to quickly recalculate formulations based on defined criteria, to create compliant products faster by using existing validated formulas. Product/Process optimization is the practice of making changes or adjustments to a process such as Conjoint Analysis, typically used in industrial process optimization.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-12: GMP in Food Industry

The Quality control in typical food processing has a significant role in assuming a high quality, safe and nutritious food supply for the public, for their good health and for the economic benefits derived from trade of safe and high quality food. Quality control conference also plays a major role in food industry. Hazard Analysis & Critical Control Points (HACCP) is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product. Food, Drug, and Cosmetic Act is a set of laws giving authority to the US-FDA to oversee the food safety, safety of drugs, and cosmetics. Cleaning, disinfection and hygiene should be strictly maintained in food industry.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-13: GMP in Microbiology and Biotechnology

Microbiological Assay is defined as the determination or estimation of concentration or potency of an antibiotic by means of measuring and comparing the area of zone of inhibition or turbidity produced by test substance with that of standard over a suitable microbe under standard conditions. FDA 510k Testing regulation is found in 21 CFR 807 includes information required in a 510(k). The 510(k) is not a form. Cleaning, disinfection and hygiene should be strictly maintained in Microbiology and Biotechnology.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track-14: Softwares in GMP and GCP

The use of GMP software systems in regulated industries is vital throughout all aspects of the manufacturing process. Quality management software provides a flexible and configurable platform for tracking and managing quality and regulatory compliance events to ensure that manufacturing activities are continually measured, monitored and improved upon. In addition to managing all aspects of the audit process, GMP software solution manages the associated findings or observations, corrective and preventive actions (CAPAs), risk assessment, risk management and the analysis and approvals of changes. This software also manages deviations, process validation, complaint handling, manufacturing incidents, training records and more.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track–15: Analytical method Quality Auditing

Quality assurance (QA) and independent audit is critical in the pharmaceutical industry to assure reliability of the products, adherence to approved specifications, and conformation of current good manufacturing practices (cGMP) to regulation. Manufacturers must establish a quality control unit that is responsible for quality-related activities required by the regulations. Quality is determined by whether the firm complies with GMP requirements and makes scientifically justified decisions. Pharmaceutical companies are now taking a proactive stance with the new GMP Systems approach, more effective internal auditing and increased regulatory awareness throughout the company.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track 16: Excipient Qualification and Supply Chain Controls

Excipients play an important role in formulating a dosage form. These are the ingredients which along with Active Pharmaceutical Ingredients make up the dosage forms. Excipients act as protective agents, bulking agents and can also be used to improve bioavailability of drugs in some instances, Excipients affect the physicochemical characters of the active pharmaceutical ingredient which may lead to formation of molecular complexes, increase in rate of chemical degradation etc.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track 17: Quality Management System in Testing Laboratories

Testing laboratories provide vital services to their customers who expect accurate results produced at appropriate time and at reasonable cost. Adoption of the quality management system (QMS) by a laboratory would facilitate achieving these goals. The International Organization for Standardization (ISO) has developed an international standard, known as ISO 17025: 2005 ‘General requirements for the competence of testing and calibration laboratories’, for the accreditation of testing laboratories to a wide range of testing environments. Compliance with this quality standard requires that the laboratory shall establish and maintain a systematic way to ensure and improve its performance. Compliance with the ISO 17025 provides a unique focus for assuring implementation of the QMS and technical competence of a laboratory.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track 18: Importance of Audit in Pharmaceutical Industry

International Organization for Standardization (ISO) 9000 requirements do not have the same status of “the law” in the U.S. as do requirements listed in the Code of Federal Regulations (CFR). Because 21 CFR 210 and 211 have legal status, the U.S. Justice Department has extensive powers to ensure compliance. For example, product in the marketplace can be seized, fines can be levied, and personal liability can be assigned. So, management must understand that auditing must be taken seriously, and the requirements listed are just that – requirements. While audits are the common place in the pharmaceutical industry, the preparedness for those events varies. The companies that develop a risk-based approach to audits are able to remain competitive while meeting quality and government compliance standards on a regular basis. Conversely, the companies that have not implemented strong processes are putting themselves at risk for non-compliance. According to the Federal Food, Drug and Cosmetic Act, “Registered domestic drug establishments shall be inspected by the FDA at least once every two years.” Under some conditions the inspections may be even more frequent, As regulations become more stringent, regulatory authorities are likely to step up audits which is even more reason for companies to be prepared.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track 19: Quality Assurance Audits in Pharma Industries

The quality of pharmaceuticals has been a concern of the World Health Organization (WHO) since its inception. The setting of global standards is requested in Article 2 of the WHO Constitution, which cites as one of the Organization’s functions that it should “develop, establish and promote international standards with respect to food, biological, pharmaceutical and similar products.” The supply of essential medicines of good quality was identified as one of the prerequisites for the delivery of health care at the International Conference on Primary Health Care in Alma-Ata in 1978. Similarly, the Conference of Experts on the Rational Use of Drugs, held in Nairobi in 1985, and WHO’s Revised Drug Strategy, adopted by the World Health Assembly in May 1986, identified the effective functioning of national drug regulation and control systems as the only means to assure safety and quality of medicines.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track 20: Auditing Deviations, Product Complaints, and CAPA Systems

Among the essential elements of a well-established Quality Management System (QMS), deviation handling plays a key role in assuring quality in products and by contributing to continuous improvement. Manufacturers are expected to “establish processes and define appropriate controls for measurement and analysis to identify nonconformities and potential nonconformities, defining when and how corrections, corrective actions, or preventive actions should be undertaken. These actions should be commensurate with the significance or risk of the nonconformity or potential nonconformity. GMPs have evolved as a consequence and of the inherent risks to the product during manufacturing operations in order to prevent significant deviations. More recently, Quality Risk Management (QRM) has been proposed as a strategy to manage risk in a systematic and documented manner, and has become a requirement of modern GMPs as recommended by international standards like WHO or ICH.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track 21: Goals and Strategies to Meet Audit Requirements

FDA cannot meet the goals of the Initiative alone. The success of the Initiative has been predicated on active participation and input from experts in industry, academia, government, and consumer groups. Emphasize the importance of the Initiative and look forward to many more improvements in regulatory processes for ensuring product quality. The following organizational components of FDA have been actively involved in working toward this modernization over the last four years: ORA, Center for Biologics Evaluation and Research (CBER), Center for Drug Evaluation (CDER) and the Center for Veterinary Medicine (CVM), along with various offices within the Office of the Commissioner. All of these organizations continue to promote the goals and objectives of the Initiative and are dedicated to continuing to improve the regulation of pharmaceuticals in the 21st Century.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track 22: Pharmaceutical Auditing for OTC Drugs

Non-prescription medicines, commonly known as over the counter or OTC medicines, are used for treatment. Sales of over the counter medicines in pharmacy and grocery outlets reached £2.45bn in 2017, up by £52.3m compared with the previous year. In the late 1980s the government fuelled the over the counter market by making it easier to reclassify certain medicines from prescription only status to allow over the counter sale in pharmacies. Although all non-prescription medicines are required to hold a product license, few have been evaluated in formal clinical trials in the setting in which they will be used. As a result many non-prescription products sold by pharmacists have been criticized for their lack of effectiveness. There are three legal categories of medicines prescription only medicine (POM), pharmacy medicine (P), and general sales list medicine (GSL); the last can be sold from outlets including supermarkets and drugstores. The principle of a class of medicines whose sale requires the supervision of a pharmacist is not unique to the United Kingdom.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track 23: Clinical and Bioanalytical laboratory Audits

One of the critical tasks for a Good Laboratory Practices (GLP) nonclinical laboratory study or Clinical Trial team is choosing a bioanalytical laboratory vendor that will meet their study needs. A well-managed bioanalytical study with proper Sponsor oversight will go a long way to ensure the generation of accurate data and quality data. Many companies have a Research & Development Quality Unit that includes people with auditing skills in Good Clinical Practices (GCPs) and Good Laboratory Practices (GLPs). Many R&D auditors have a background in what is required to audit a bioanalytical laboratory for either Clinical trials, GLP, GLP-Like or best laboratory practices.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track 24: Clinical Audit in Pharmaceutical Development

Clinical quality assurance audits, performed to ensure that scientific and ethical standards are met in the conduct of clinical trials, are conducted using proprietary computerized audit tools, customized to each project, so that GCP audit findings can be efficiently and consistently collected, analyzed and reported. This focused systems-oriented approach to quality assurance is designed to assess and validate study conduct and documentation to ensure regulatory compliance and conformance to protocol, SOP and contractual requirements. Methodology should evaluate the activities and documentation underlying study data integrity and Good Clinical Practice (GCP) ethical and regulatory requirements.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

Track 25: Quality Assurance, Quality Control and Audit

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria that meets the requirements of the client or customer. A major aspect of quality control is the establishment of well-defined controls. These controls help standardize both production and reactions to quality issues. The role of Quality Impact Assessment & effectiveness checks is an essential operation of the pharmaceutical industry. To Perform Quality Control process of Project Management several quality control tools and software’s are required. Quality control also plays a major role in analytical method development.

Related Conferences:

20th International Conference on Good Manufacturing Practice, Manufacturing Dynamics and Developments May 17 -18 2018 Barcelona, Spain; 42nd International Good Manufacturing Practices Conference March 12 -15 2018 Athens. Georgia, USA; Manufacturing and Technology Conference & Expo May 8-10 2018 Raleigh, North Carolina, USA; Pharmaceutical Auditing June 08-09 2018 Philadelphia, USA.

For conference attendance and participation only Business Visa should be applied. Contact your nearest travel agent/visa information center/US Embassy for the correct application form.

All visas for visiting US shall be processed by respective authorities only upon submission of proper documents through proper channel.

In case of non-furnishing of documents, non-adherence to guidelines visas shall be cancelled by respective authorities.

The minimum supportive documents that might be required while applying for US visa include:

- Letter of invitation

- Abstract acceptance letter (if speaker)

- Registration payment receipt

- Accommodation confirmation letter issued under conference letter head.

For letter of invitation and accommodation confirmation, payment of registration fees and accommodation charges is a pre-requisite.

Mandate documents required from conference secretariat should be obtained only through Victor Oliver or Will Thomas.

For more details please contact

Victor Oliver

Program Manager

GMP Summit 2018

E: gmpsummit@conferencesamerica.org

Global Market Analysis for GMP:

The global market for pharmaceutical and biopharmaceutical contract manufacturing, research and packaging was $219.9 billion in 2012. This market is estimated to reach $242.2 billion in 2013 and $374.8 billion by 2018, a five-year compound annual growth rate (CAGR) of 9.1%.

GLOBAL Statistics:

• Global spending on medicines is forecast to reach nearly $1.3 trillion by 2018

• 21 pharmerging countries will increase their contribution to growth over the next five years and account for nearly 50% of absolute growth in 2018.

• The pharmerging markets will expand at a compound annual growth rate of 8-11% through 2018

• Total global spending will reach $1.3 trillion in 2018, an increase of $290-320 billion from 2013, driven by population growth, an aging population, and improved access in pharmerging markets.

• A compound annual growth rate of 4-7% on a constant currency basis, will be slightly higher than the 5.2% recorded over the past five years

Global Market Analysis for GCP:

"Good clinical practice", was developed under the auspices of the International Conference on the Harmonization of the Technical Requirements for the Registration of Human Pharmaceuticals (ICH process) and is applicable in the European Union, the United States and Japan.

The Global Clinical trial management system Market is expected to reach Significant Market Size by the end of the forecasted period and is expected to grow at a CAGR of ~15%.

IMS Market Prognosis 2012 predicted the pharma market in Asia (excluding Japan) to reach $350 billion by 2016 – $80 billion of this from China, but the majority from these other less talked about markets. This accounts for 30% of the $1.2 trillion that makes up the global pharma market. Each country’s government has recognized the opportunity this industry can bring to national development, and are therefore focused on supporting and investing in the sector.

Global Market Analysis for Regulatory Affairs:

Regulatory Affairs Department is the backbone of Pharmaceutical Industry. It is the revenue generator for pharmaceutical Industry. The Regulatory Affairs department is an important part of the pharmaceutical companies.

More than 15 years span is required to develop and launch a new pharmaceutical product in the market. The Regulatory Affairs Agencies explains expenditure spent on each drug annually is $850 million in US. The Indian Pharmaceutical industry is one of the fastest growing industries in India, with a compounded annual growth rate (CAGR) of over 13 % in last 5 years and it is expected to grow at a higher rate in coming 10 years where India spends around $300 million, united kingdom $700 , Brazil $200 million , France $550, Italy $400. As per cabinet decision in June 2010 Japan amended a new policy i.e., Health power strategy through “Life Innovation” with an expenditure spent on each drug was $450 million.

Internally it cooperates with other department like drug development, manufacturing, marketing and clinical research. Externally, it is the key interface between the company and the regulatory authorities. Industrialized regulatory affairs are to drive compliance, speed to market, and cost efficiency.

Global Statistics:

· Market revenue in terms of US$ Million for the period between 2013 and 2023 along with the compound annual growth rate (CAGR %) from 2015 to 2023 are provided for all the segments, considering 2014 as the base year.

· Product development, research, and commercialization units are being set up at an increased rate across emerging economies owing to cheap resources and raw material costs.

· The vast population base of Asia Pacific also makes it a lucrative regional market for the medical industry. These factors are acting in favor of the regulatory affairs outsourcing markets in these regions and will help strengthen the market’s foothold in the next few years.

· As a result, the market for regulatory affairs outsourcing market in emerging economies will offer the most lucrative and sustained growth opportunities for the global market.

· The market is expected to expand at a 15.8% CAGR in Asia Pacific and 11.1% CAGR across Latin America from 2015 to 2023.

· The global regulatory affairs outsourcing market is expected to reach USD 12.4 billion by 2025.

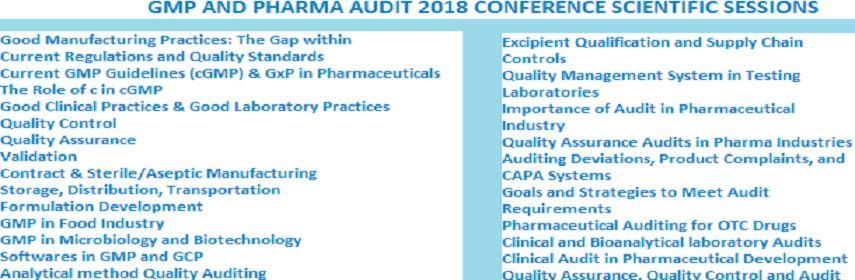

Conference Highlights

- Good Manufacturing Practices: The Gap within

- Current Regulations and Quality Standards

- Current GMP Guidelines (cGMP) & GxP in Pharmaceuticals

- The Role of c in cGMP

- Good Clinical Practices & Good Laboratory Practices

- Quality Control

- Quality Assurance

- Validation

- Contract & Sterile/Aseptic Manufacturing

- Storage, Distribution, Transportation

- Formulation Development

- GMP in Food Industry

- GMP in Microbiology and Biotechnology

- Softwares in GMP and GCP

- Analytical method Quality Auditing

- Excipient Qualification and Supply Chain Controls

- Quality Assurance Audits in Pharma Industries

- Quality Management System in Testing Laboratories

- Importance of Audit in Pharmaceutical Industry

- Auditing Deviations, Product Complaints, and CAPA Systems

- Goals and Strategies to Meet Audit Requirements

- Pharmaceutical Auditing for OTC Drugs

- Clinical and Bioanalytical laboratory Audits

- Clinical Audit in Pharmaceutical Development

- Quality Assurance, Quality Control and Audit

To share your views and research, please click here to register for the Conference.

To Collaborate Scientific Professionals around the World

| Conference Date | June 08-09, 2018 | ||

| Sponsors & Exhibitors |

|

||

| Speaker Opportunity Closed | Day 1 | Day 2 | |

| Poster Opportunity Closed | Click Here to View | ||

Useful Links

Special Issues

All accepted abstracts will be published in respective Our International Journals.

- Journal of Developing Drugs

- Pharmaceutica Analytica Acta

- Pharmaceutical Regulatory Affairs: Open access

Abstracts will be provided with Digital Object Identifier by